Applications

Applications

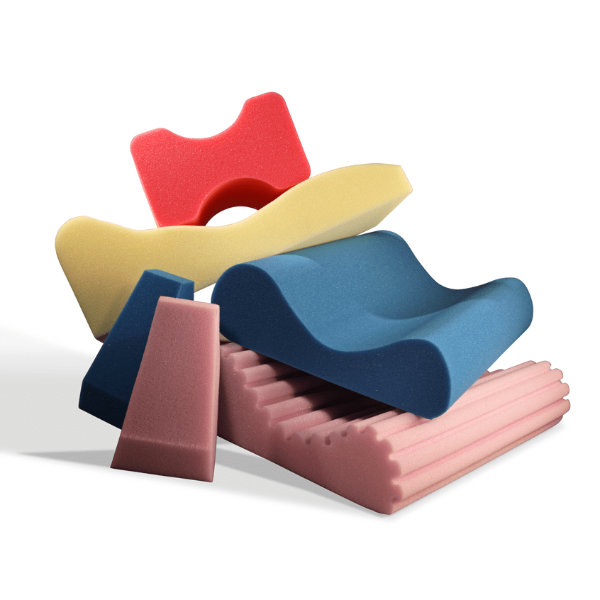

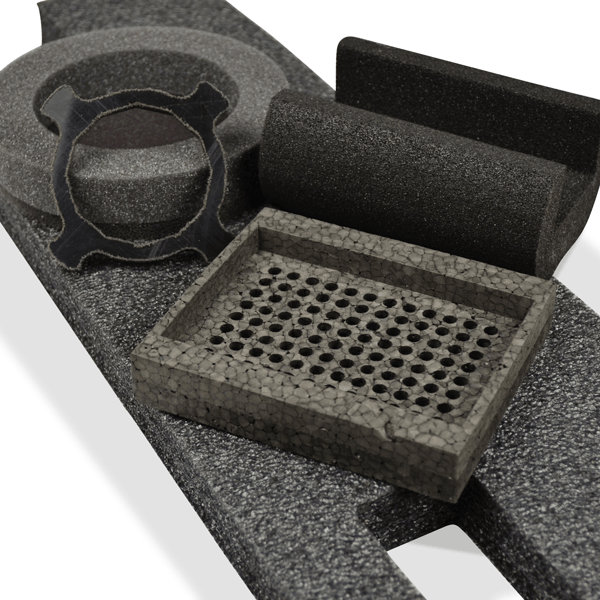

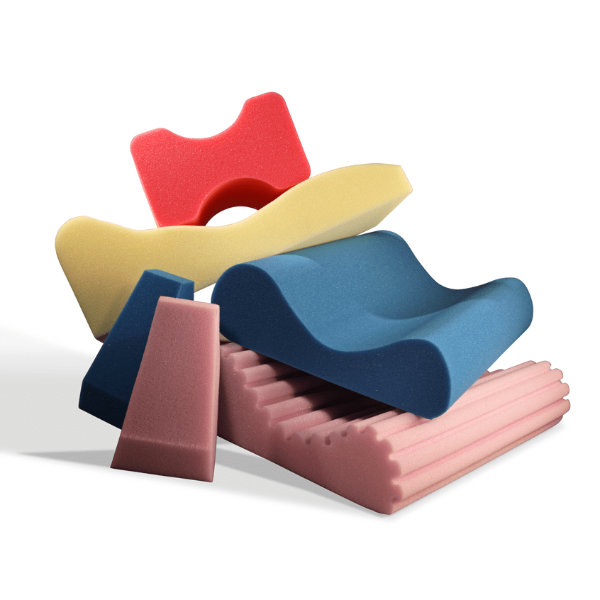

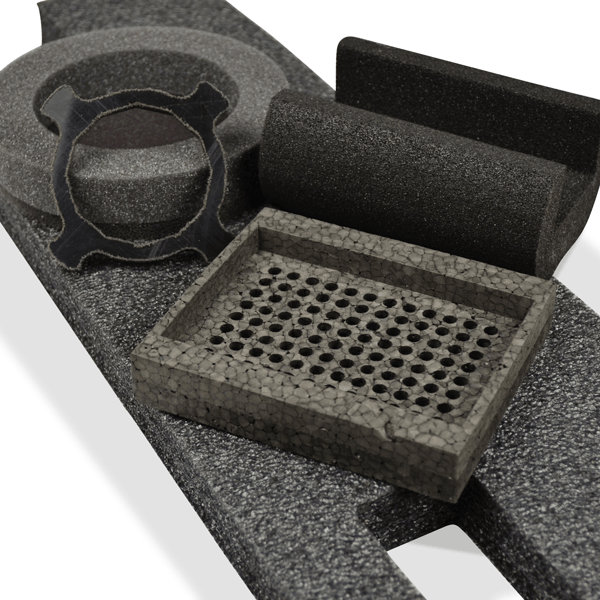

Custom foam fabrication for any industry application

With more than 40 years of foam fabrication experience and an unmatched range of material options, Foam Fabricators of Minnesota has the capability to create custom foam products for any industry application. From custom protective packaging to foam case inserts and handling trays, cushioning for personal or healthcare use, and corrugated shipping boxes, Foam Fab is your one stop shop for all things foam. Our team of expert product designers and fabricators use cutting edge design applications and production equipment to manufacture a nearly endless range of commercial grade foam products, shipping boxes and so much more.

Whether you are looking for a single prototype or a large production run, we can fulfill your order. We offer a large variety of foam materials that include polyethylene, polyurethane, beaded polyethylene, crosslinked polyethylene and expanded polystyrene, among others. Our large-scale production facility, expansive fabricating capabilities and experienced team of designers, engineers and fabricators keep our turnaround times short and our production costs low, allowing you to get the precise products you need, when you need them.

OUR FABRICATING

Capabilities

Have a custom prototype and need a scale model or quick assembly? Our precision capabilities allow us to create any part based on your specifications, allowing you to quickly move one step closer to your first production run.

Our broad range of classic and CNC contour applications allow for complex cut-out shapes of any size, shape and complexity. Our range of custom die cutting services include common steel rule dies, compound matched-metal dies, flash cutting and so much more. We can also convolute foam, creating a classic “egg-crate” surface.

Our precision water jets can allow us to fabricate and shape a wide variety of foam products at a low cost and with a quick turnaround time. Everything from foam packaging materials to special case inserts can be custom cut to your precise specifications.

We use a comprehensive set of wire saws, drills, and routers to shape foam based on your precise specifications. Any size, shape and number of parts can be achieved through abrasive wire cutting, CNC routing, CNC pattern cutting, vertical or horizontal contour cutting, vacuum or roll skiving, and other custom fabricating applications.

We offer several foam lamination methods, including heated plank lamination, to create simple and complex buildups. Choose between a variety of foams to create multi-layer composite products or create single material foam products with a custom thickness.

OUR FABRICATING

Capabilities

Design and Prototyping

Have a custom prototype and need a scale model or quick assembly? Our precision capabilities allow us to create any part based on your specifications, allowing you to quickly move one step closer to your first production run.

Die Cutting

Our broad range of classic and CNC contour applications allow for complex cut-out shapes of any size, shape and complexity. Our range of custom die cutting services include common steel rule dies, compound matched-metal dies, flash cutting and so much more. We can also convolute foam, creating a classic “egg-crate” surface.

Water Cutting

Our precision water jets can allow us to fabricate and shape a wide variety of foam products at a low cost and with a quick turnaround time. Everything from foam packaging materials to special case inserts can be custom cut to your precise specifications.

CNC Cutting

We use a comprehensive set of wire saws, drills, and routers to shape foam based on your precise specifications. Any size, shape and number of parts can be achieved through abrasive wire cutting, CNC routing, CNC pattern cutting, vertical or horizontal contour cutting, vacuum or roll skiving, and other custom fabricating applications.

Foam Cutting

We offer several foam lamination methods, including heated plank lamination, to create simple and complex buildups. Choose between a variety of foams to create multi-layer composite products or create single material foam products with a custom thickness.

Our Custom Products

Our Custom Products